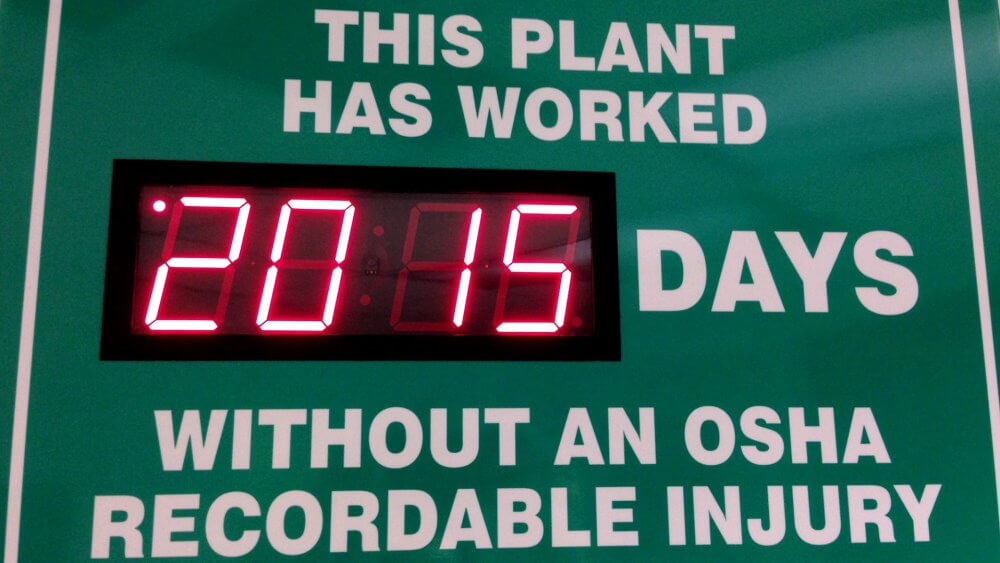

At the entrance of nearly every industrial site, you’ll find a simple counter, updated daily, meant to promote awareness, caution, and pride. But what happens when that number resets? Every zero tells a story: of an injury, of equipment damage, of something that went wrong. The number should stay high, and technology is designed to help make that possible.

Preventing human errors with valve interlocks

Human error is still one of the most common causes of process safety incidents. In systems where valves must be operated in a strict sequence, such as in pigging, loading, or high-pressure applications, a single wrong move can lead to severe consequences. Mechanical valve interlocks eliminate that risk by enforcing the correct operating sequence, physically preventing a valve from being opened or closed out of order. This removes the uncertainty from high-stakes operations and ensures process integrity is maintained.

Reducing physical strain with portable valve actuators

Manual valve operations are often repetitive, physically demanding, and potentially hazardous, especially in areas where torque values are high. This strain increases the risk of musculoskeletal injuries, operator fatigue, and errors. Portable valve actuators remove the physical burden from operators, by allowing them to operate valves quickly, safely, and without exerting excessive force. By automating a traditionally manual process, we reduce injury risk and ensure that even high-torque valves can be handled without compromising operator safety.

Keeping operators out of danger with remote manual valve operators

Not all valves are easy to reach. Many are located in hard-to-access or hazardous environments, because of heights, confined spaces, or areas with high temperatures or toxic exposure risks. Remote valve operators solve this by relocating the manual interface of a valve to a safe, convenient position, up to 30 meters away. This enables personnel to operate valves from a secure location, drastically reducing exposure to physical and environmental dangers.

Clear information with manual valve position indicators

Operators can only act on the information they have, and valve position is a key data point. Yet in many plants, valve status is still determined by guesswork, handwritten tags, or unclear indicators. Valve position indicators for linear manual valves deliver clear, unambiguous information on whether a valve is open or closed. These solutions improve situational awareness, reduce operator error, and support safer plant operations.

Keeping the number high

To make manual valve operations safer, more reliable, and more transparent, industries should focus on removing guesswork, reducing physical risk, and guiding human actions. To keep the number high, we should help operators make the right move every time. because ultimately, no one wants to see that accident counter reset.