Sofis valve interlock inspection programs prevent undesirable, costly, and even dangerous situations. They also help you ensure long term continuity of your valve interlock systems.

Recurring inspection and functional checks of your valve interlocks and supporting safety systems

Understanding the status of you valve interlocks

Sofis valve interlocks are designed to be extremely robust. When operated correctly, Sofis interlocks last for more than 20 years. Still, interlocks sometimes do get broken, bypassed and removed, in particular by operators and maintenance engineers. Understanding the status of your interlocks and recording of failures is therefore of key importance. Knowing the cause of the malfunction allows you to adequate plan follow-up action and eventually reduce the number of defects.

Recurring inspections

Many Sofis customers participate in recurring inspection of their valve interlocks, as part of an annual asset integrity program. Inspections provide an in-depth understanding of the status of your valve interlocks all related safety systems. This allows you to manage your assets and efficiently plan maintenance activities, avoiding ad-hoc repair jobs.

Inspection programs

During an inspection of your valve interlock systems, so called ‘hidden defects’ can be identified. These are critical safety risks that can lead to problematic situations that need to be addressed immediately and require an ad-hoc solution. This should be avoided at all times, especially in times where you can expect an increasing number of challenging situations, such as limited access to plants, decreased team capacity and budget limitations.

Visual inspection

Visual check of all valve interlocks and key cabinets to determine the general condition of the equipment (e.g. missing locks, abuse, damages, tagging, etc.). When the service engineer will encounter a small defect in the field (missing screws or loose parts) he will either fix it on the spot or decide to functionally test (part of the) equipment.

Functional test

During a functional check of your valve interlocks, all interlocks and cabinets are inspected to determine the condition of your equipment (e.g. missing locks, abuse, damages, tagging, etc.). During the functional test, the actual functionality of an interlock or interlock system (multiple interlocks in a sequence) will be thoroughly tested.

What does it bring you?

An inspection of your valve interlocks, performed by Sofis, provides you with:

- an up-to-date overview of the interlock install base on item level;

- a full report of product and system status (per severity level);

- a root cause analysis, providing in-depth insight in root cause;

- a corrective an preventive actions proposal plan, to ensure continuity;

- direct input for the annual maintenance plan, prioritizing and planning corrective an preventive actions;

- ensured long-term integrity of your critical safety systems, life extension planning;

- an integrity certificate, confirming that inspection took place and corrective actions were executed.

Asset integrity and continuity program

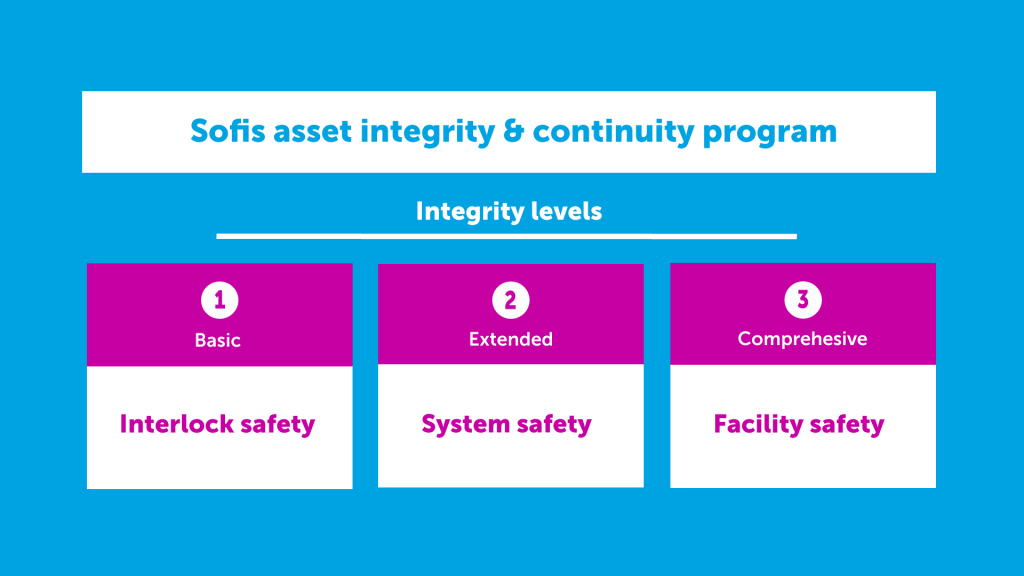

Valve interlock inspections are part of Sofis Asset integrity and continuity program.