Lining up manual valves comes with uncertainties from lacking insight in valve positions. This process can be controlled with extensive communication, double checks and valve lock-outs. However, with the use of valve monitoring, these procedures are no longer necessary for flawless operations.

Ensure correct line-ups with real-time valve monitoring

With valve position indicators you gain real-time insight in your valve line-ups

- Valve status information in the control room makes double checks unnecessary

- Status changes are instantly visible, making lock-out obsolete

- Mistakes are instantly noticed so you can rectify them before they cause issues

Gain insight into your existing manual valves

By adding VPI position indicators you obtain digital feedback about manual valve positions. They are easily retrofitted to any manual valve.

The VPI signals real-time position information to your control room. It is connected to your control system or a remote interface with a wired or wireless connection.

Your operator receives operating instructions

Based on the required line-up, your operator receives valve operating instructions.

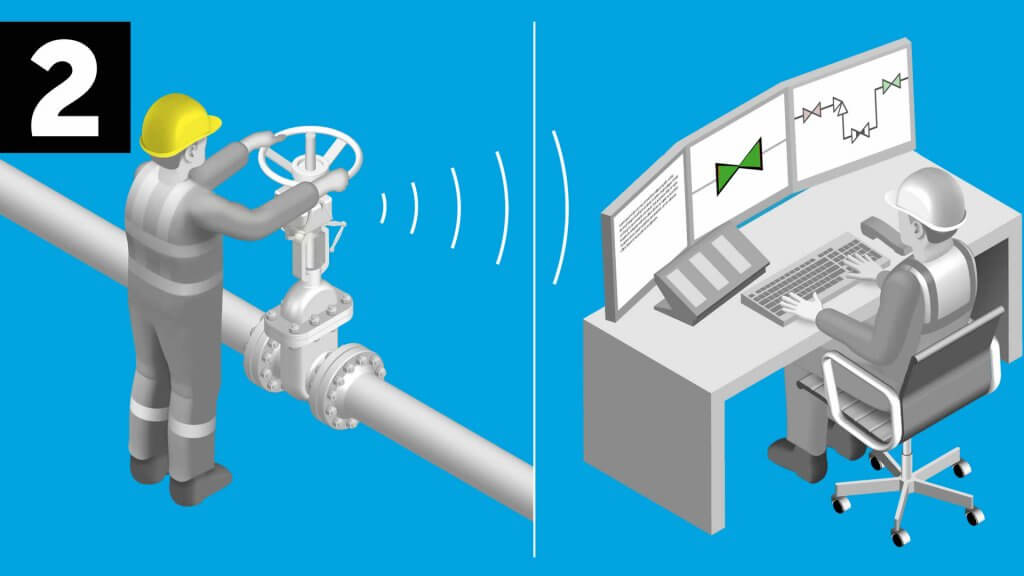

Your control room receives real-time valve status updates

Manual valves are equipped with valve position indicators. They detect changes in the valve position which are signalled to the control room in real-time.

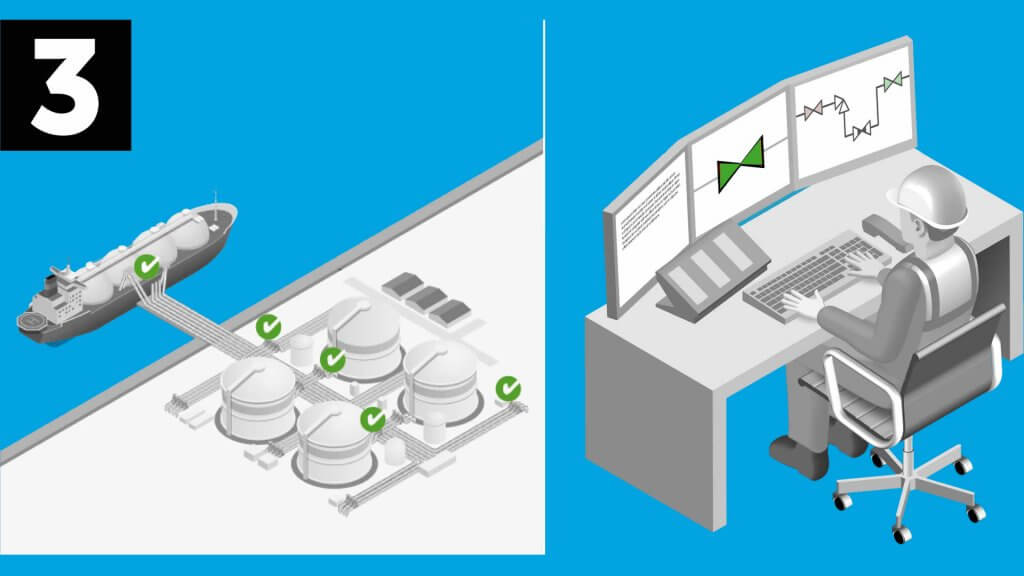

Pump start-up is conditioned based on valve line-up status

Your control system receives status updates from all manual valves in the field. These signals can be displayed on an interface in your control or used as inputs in your DCS.

Cases

Growing terminal throughput with faster line-ups

We have helped a large European refinery improving its tank farm throughput. To prepare a product transfer, large numbers of valves need to be lined-up manually. By speeding up this process, the terminal can serve about 80 ships annually, worth €2M+ of extra revenue.

Eliminating contamination risks with manual valve position indicators

A large Spanish refinery with a large tank farm storing approximately 2.500.000 m3 of petroleum products in various qualities. Soon after installation, a first line-up error was discovered. This saved €300.000 – €500.000.

What our customers say

Fast line-ups don’t require automation

In today’s challenging market conditions, terminal operations such as lining up valves for product transfer, must be performed efficiently. However, most terminals rely on manual operations. Luckily, manual valve operations can be significantly accelerated and secured, without the need for complete actuation and automation of all valve operations.