Manual valve operations are a critical component of industrial plant safety, and valve interlocks play a crucial role in ensuring that these operations are carried out in the correct sequence. But without effective key management, valve interlock systems can fall short. Disorganization, lost keys, and knowledge gaps among operators create unnecessary risks, and that’s where key management systems make the difference.

How key management systems improve safety and control

Valve interlocks are designed to enforce safe operating procedures by ensuring that valves are opened or closed in a specific, predefined sequence. They prevent human error by ensuring valves are opened or closed in the correct order. However, valve interlocks are limited in that they do not monitor the state of surrounding systems, nor do they provide real-time system-wide awareness, which limits their ability to provide full context before a valve changeover. Another common problem lies in the basic key cabinets. Keys are often misplaced, not returned to their assigned slots, or lost. This lack of control means plant personnel can’t quickly assess the real-time status of all interlocked valve systems, a critical function in daily operations and emergencies. When a key goes missing and an urgent valve change is required, things can quickly escalate. Inexperienced operators might not know how to respond, increasing the risk of incorrect actions and potential safety incidents.

Bridging the gap with key management systems

Integrating a key management system with valve interlocks solves many of these challenges. These systems transform disorganized key cabinets into intelligent hubs of information and control. With a key management system, every key transaction is logged. The system tracks who used which key, when, and where. If a key is missing, it’s instantly flagged and its last user is recorded, eliminating guesswork and speeding up recovery.

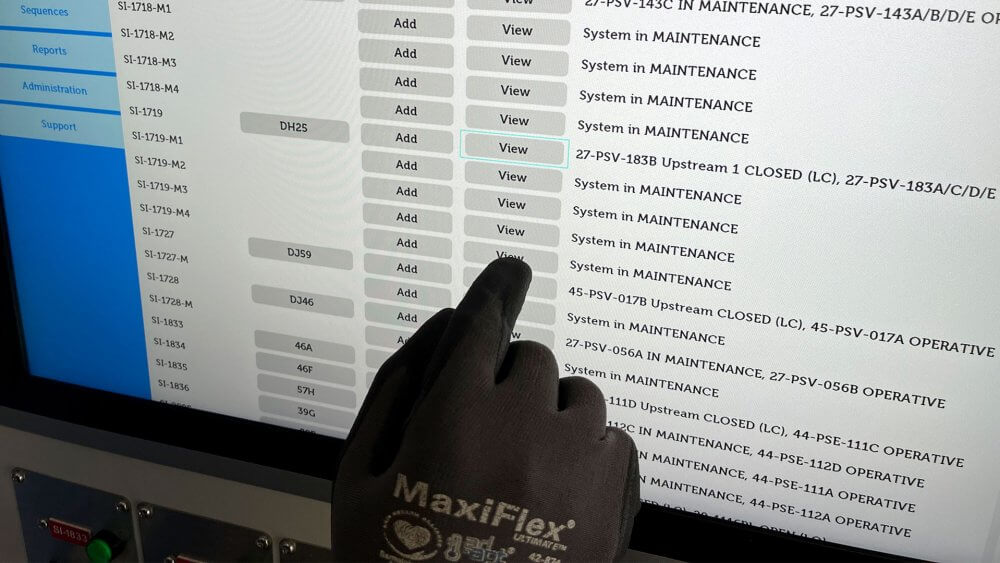

Guiding operators with technology

Modern key management systems do more than track valve interlock keys; they actively assist operators. LED indicators highlight the correct return position of each key. Touchscreens display detailed valve operation steps. This clear, visual guidance reduces the risk of human error and helps ensure that every action taken aligns with approved procedures. These features are especially valuable for less experienced staff, giving them the confidence and clarity needed to operate safely and effectively from day one.

Turning data into performance insights

Every time a valve interlock key is used, it generates data. That data, when captured and analyzed, provides powerful insights into manual valve operations. You can monitor valve usage trends, track asset performance, and even detect bottlenecks or inefficiencies in real-time. Knowing which valves are accessed most often and under what conditions allows maintenance planning to become smarter and more proactive. This operational transparency supports plant-wide performance improvements and enhances compliance.

From safety to strategy

Key management systems don’t just make operations safer, they make them smarter. They close the gap between isolated valve interlock systems and integrated plant intelligence. By combining physical safety mechanisms with digital management tools, you create a system that protects people, assets, and performance alike.

Ready to upgrade your valve interlock operations?

Discover how Sofis key management systems can transform your manual valve procedures.