Flawless manual valve line-ups will avoid loading incidents and speed up operations at the same time. You can ensure a correct manual valve line-up either by electronically monitoring manual valve positions or by regulating your manual operations. Our valve position indicators allow you to always have real-time insight into the status of your manual valves. Our valve line-up solution lets your control system regulate your manual valve operations, providing maximum control and insight.

Avoid cargo loading incidents

Transfer more product

Multiple ways to ensure correct valve line-ups

Total control over your manual valve operations

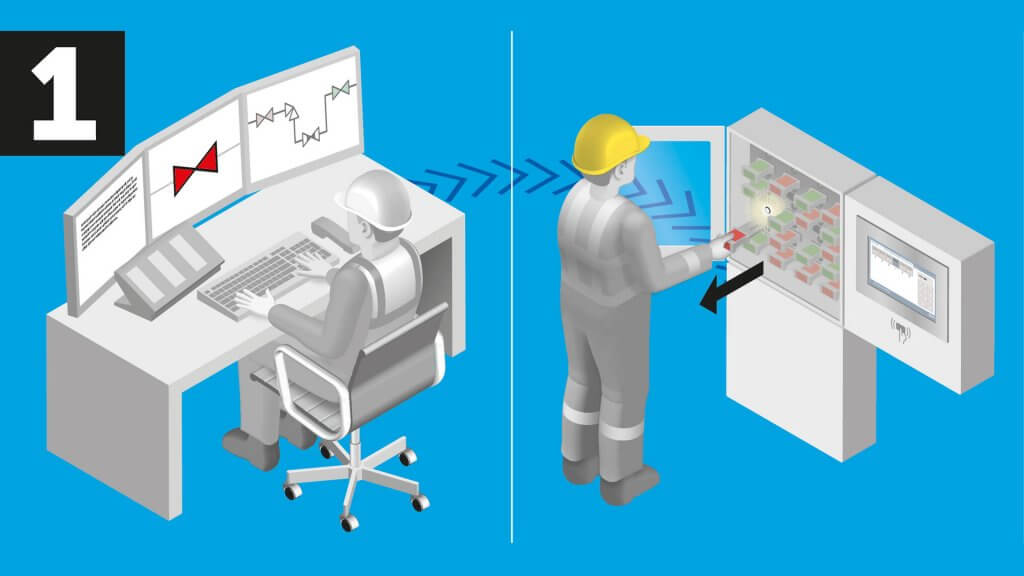

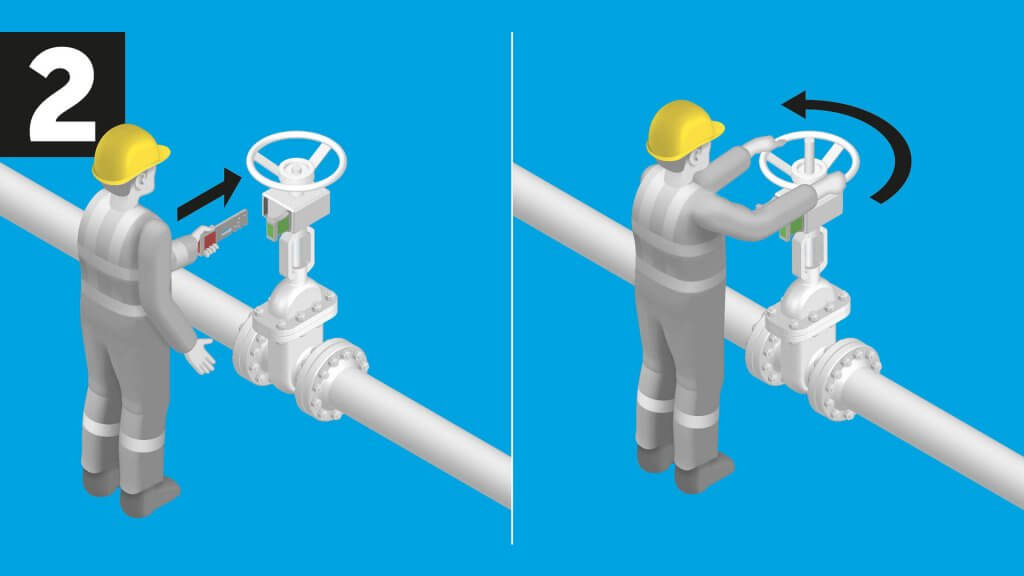

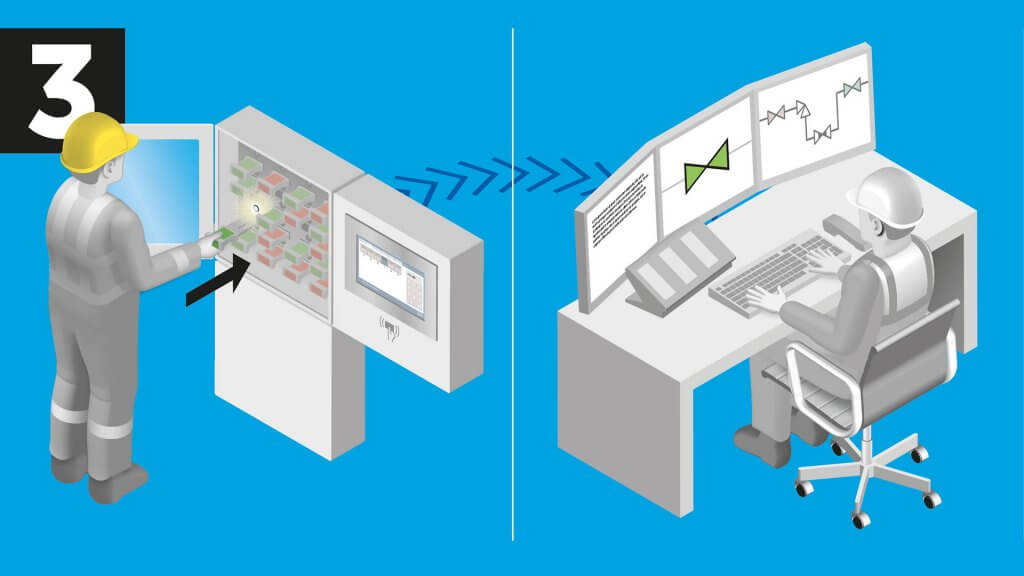

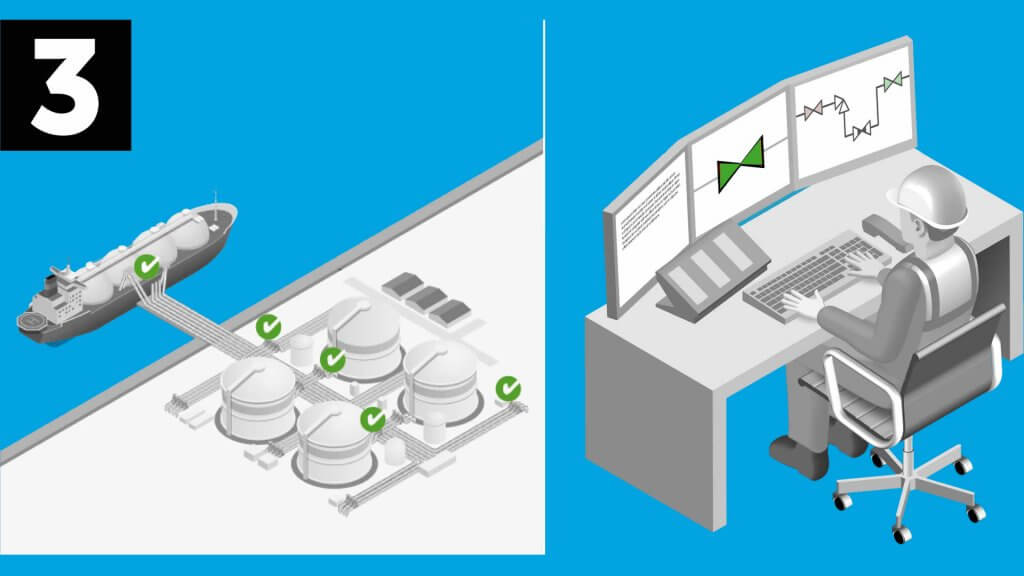

With our valve line-up system, you’ll leave no room for incidents and ensure fast and flawless operation. Your control system regulates your manual valve operations, providing maximum control and insight.

Your DCS determines which valves are to be operated.

You can only operate the nominated valves.

Product transfer will only occur with correct line-up.

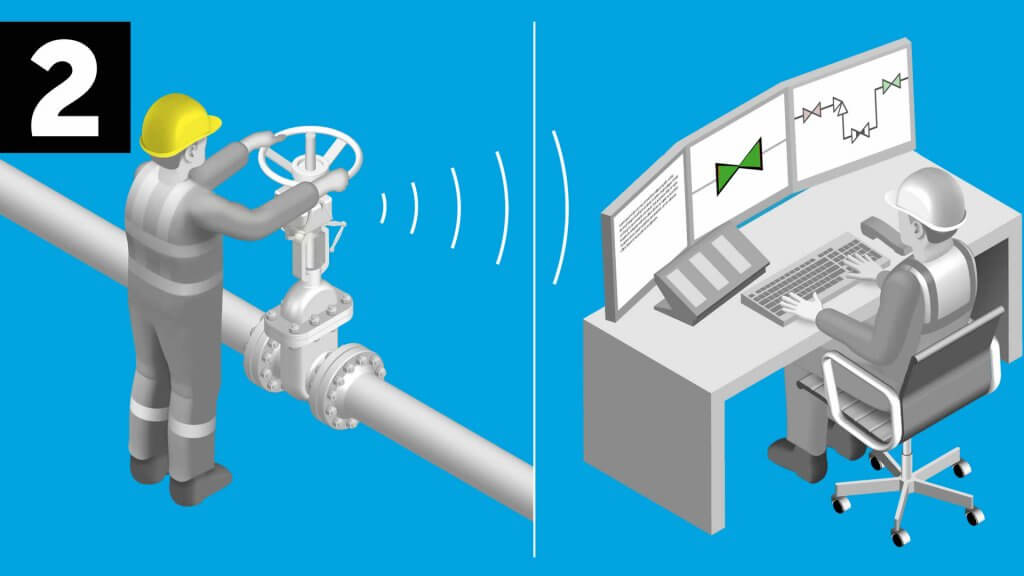

Real-time insight into your manual valve positions

With our VPI position indicators, you always have real-time insight into the status of your manual valves. Changes in valve positions are instantly detected and transmitted to your control room.

Your DCS determines which valves are to be operated.

The valve position indicator signals the positions real-time to the DCS.

The DCS can start the transfer when all valves have the right position.

More throughput. Less Investment. Zero Incidents.

By ensuring fast, first-time-right valve line-ups you increase throughput and terminal profitability, without the need for full automation.

- Eliminate the risk of product spills and contamination

- Optimize terminal throughput

- First-time-right valve operations

- Real-time availability of operational data

- Lower CAPEX compared to terminal automation

How a leading tank storage company avoids product contamination during cargo loading

In the tank storage industry, product contamination during product movements is a common issue. A leading tank storage company managed to avoid product contamination during cargo loading with a dedicated valve-line up system.

What our customers say

How to avoid cargo loading errors?

Frank Gielissen of Sofis explains how to ensure correct manual valve line-up, either by electronically monitoring manual valve positions or by regulating your manual operations.