Manual changeovers are prone to human error. Lack of experience or poor communication induce operator mistakes. When such mistakes lead to instant hazards, they must be eliminated.

Eliminate human errors from critical valve operations

Ensure safe conditions before a pig trap is opened

Daily pigging operations involve dangerous pressures and gasses. With interlocks you can avoid exposure to these hazards. They force operators to drain, vent and isolate the vessel before opening the closure door.

By interlocking your pigging operations you:

- ensure that the vessel is depressurized before it is opened

- ensure that the vessel is isolated before it is opened

- avoid that drain valves are open when the vessel is being filled

Always enough safety relief capacity

To guarantee sufficient safety relief capacity, one relief valve must be online at all times. By interlocking all block valves around the relief valves, this safety requirement is guaranteed. The interlocks enforce the opening of the path to the spare relief valve, before the other relief valve is isolated.

By interlocking block valves around your relief valves you avoid:

- that too many relief valves are blocked simultaneously

- that outlet valves are closed when inlet valves are open

Never let your pump run dry

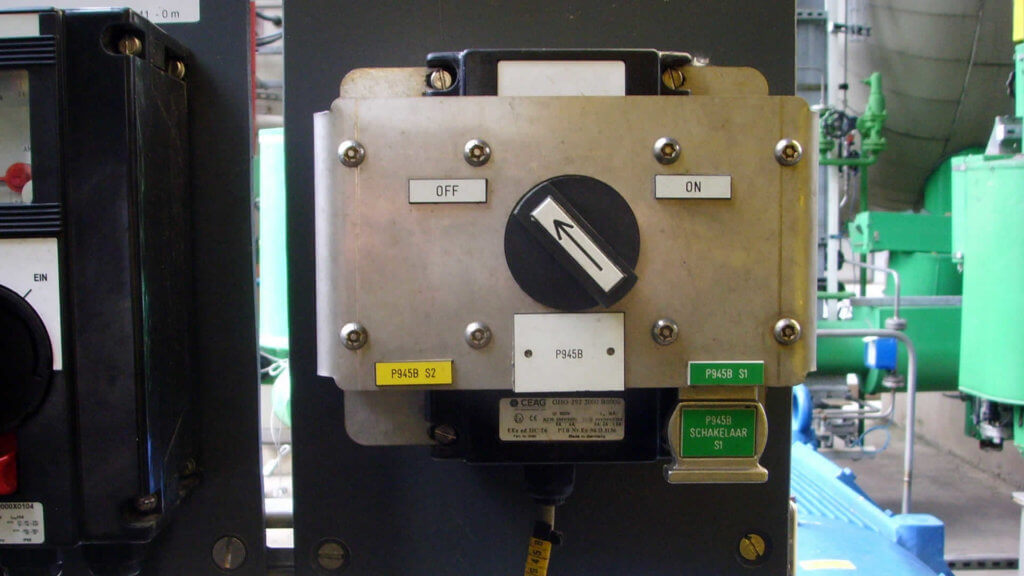

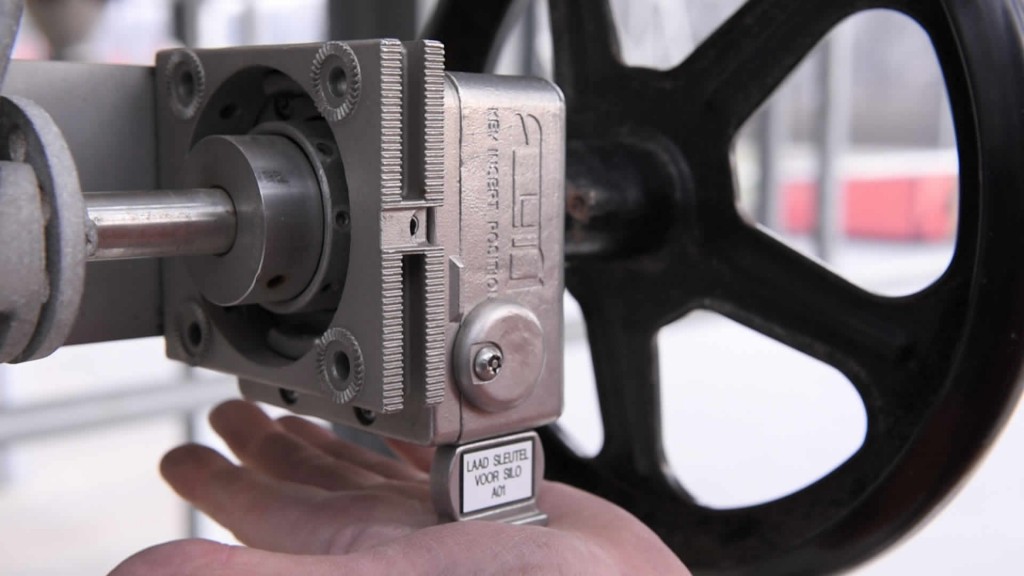

To avoid pumps running dry or overheating, you must ensure valves surrounding the pump are open before pump start-up. For locally controlled pumps you mechanically interlock these valves with the electrical pump switch. For remotely controlled pumps, the valve positions are monitored with position indicators and electronically interlocked with your pump start-up procedure.

By interlocking the valves around you should ensure that:

- the suction and discharge valves are open before operating the pump switch

- the pump is switched off before closing suction and discharge valves