How to guarantee the removal of intrusive corrosion monitoring probes, before initiating pipeline pigging operations, to avoid damage and lost time?

Guaranteeing the removal of corrosion probes

Corrosion probes, coupons, and holders are used to detect the corrosion rate of specific metals, to determine how much pipeline wall thickness is lost to corrosion in a particular amount of time. However, operators sometimes neglect to remove intrusive corrosion monitoring devices before initiating pipeline pigging operations, resulting in damaged probes.

Corrosion monitoring prevents corrosion related failures

Corrosion monitoring is an important tool in the battle against premature degradation of pipelines. The corrosion related failures in pipelines costs billions of dollars in production losses, downtime, environmental contamination, injuries, and fatalities. Most of these could be significantly reduced by employing continuous monitoring techniques as a component of comprehensive corrosion control programs.

Monitoring pipelines provides a warning of high corrosion rates, verifies the effectiveness of corrosion control, and measures loss of wall thickness, to extend asset lifespan.

Corrosion devices getting hit by pipeline pigs accidentally

Corrosion probes, coupons, and holders are used to detect the corrosion rate of specific metals, to determine how much pipeline wall thickness is lost to corrosion in a particular amount of time. Due to limited clearance space, and when 12 o’clock orientation with intrusion into the center of line or to the bottom of line is required, intrusive devices are sometimes preferred over 6 o’clock, flush mounted corrosion monitoring devices. Operators sometimes neglect to remove corrosion monitoring devices, resulting in the pipeline pig hitting corrosion probes, resulting in damage and lost time.

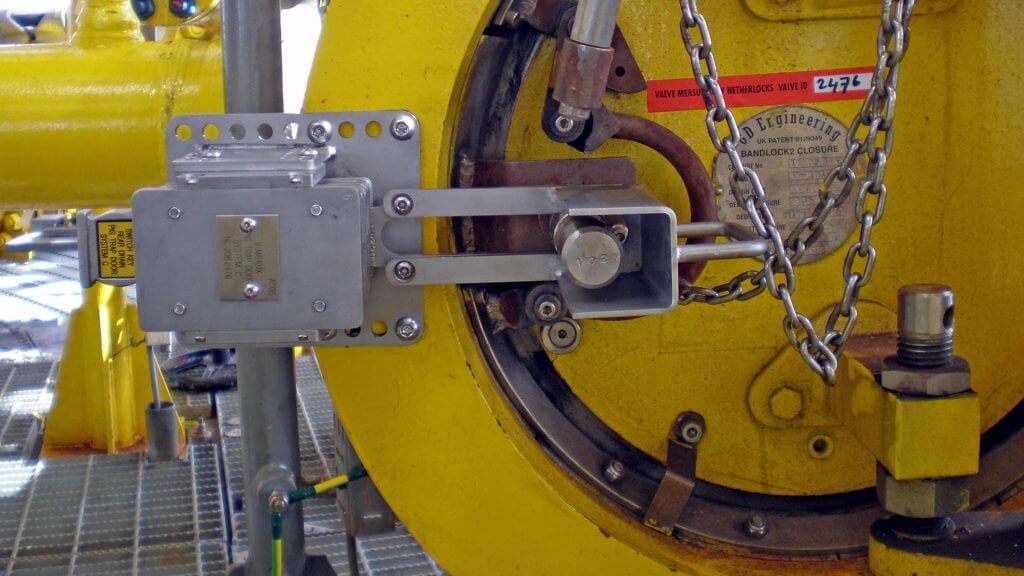

Valve interlock systems for pigging operations

Valve interlock systems provide a simple, fail-safe process that ensures accidents cannot happen during a pigging operation. They prevent operators to operate any process valve while the closure door is still open, or not in its fully locked closed position. This is because the key to start the operating sequence is still trapped in the closure door lock.

Corrosion probes are not included in secured valve operation sequences

While pig launchers and receivers are frequently equipped with mechanical valve interlocks, corrosion monitoring devices (corrosion probes and coupons) are usually not integrated in an operating sequence secured by valve interlocks.

Integrating corrosion probes into valve interlock systems

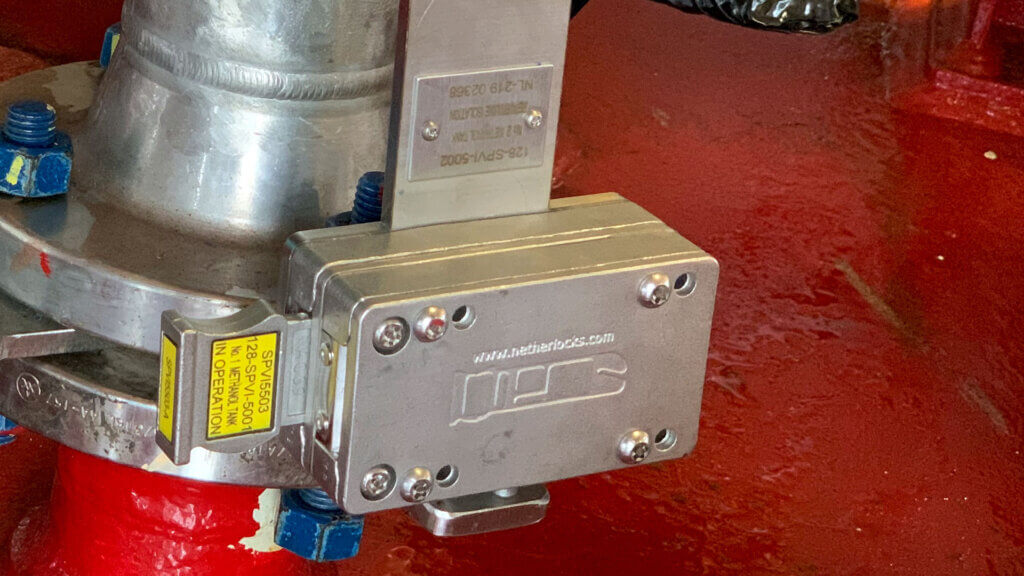

To prevent damage to intrusive corrosion probes that have not been removed before initiating a pigging operation, these probes can be easily integrated into an interlocked valve operation sequence. When a pigging operation must be carried out, corrosion probes must be taken out first, to prevent the pig getting into contact with corrosion probes.

Ensure that the coupon and probe will be retrieved from the pipeline

Removing the probe can be integrated into the interlock sequence of the pigging operation. Mechanical interlocks installed at the coupon and probe access fittings ensure that the coupon and probe will be retrieved from the pipeline prior to the start of pigging operation. This solution has proven to be very successful and is now a standard Sofis product to integrate corrosion probes in interlocked pigging operations.